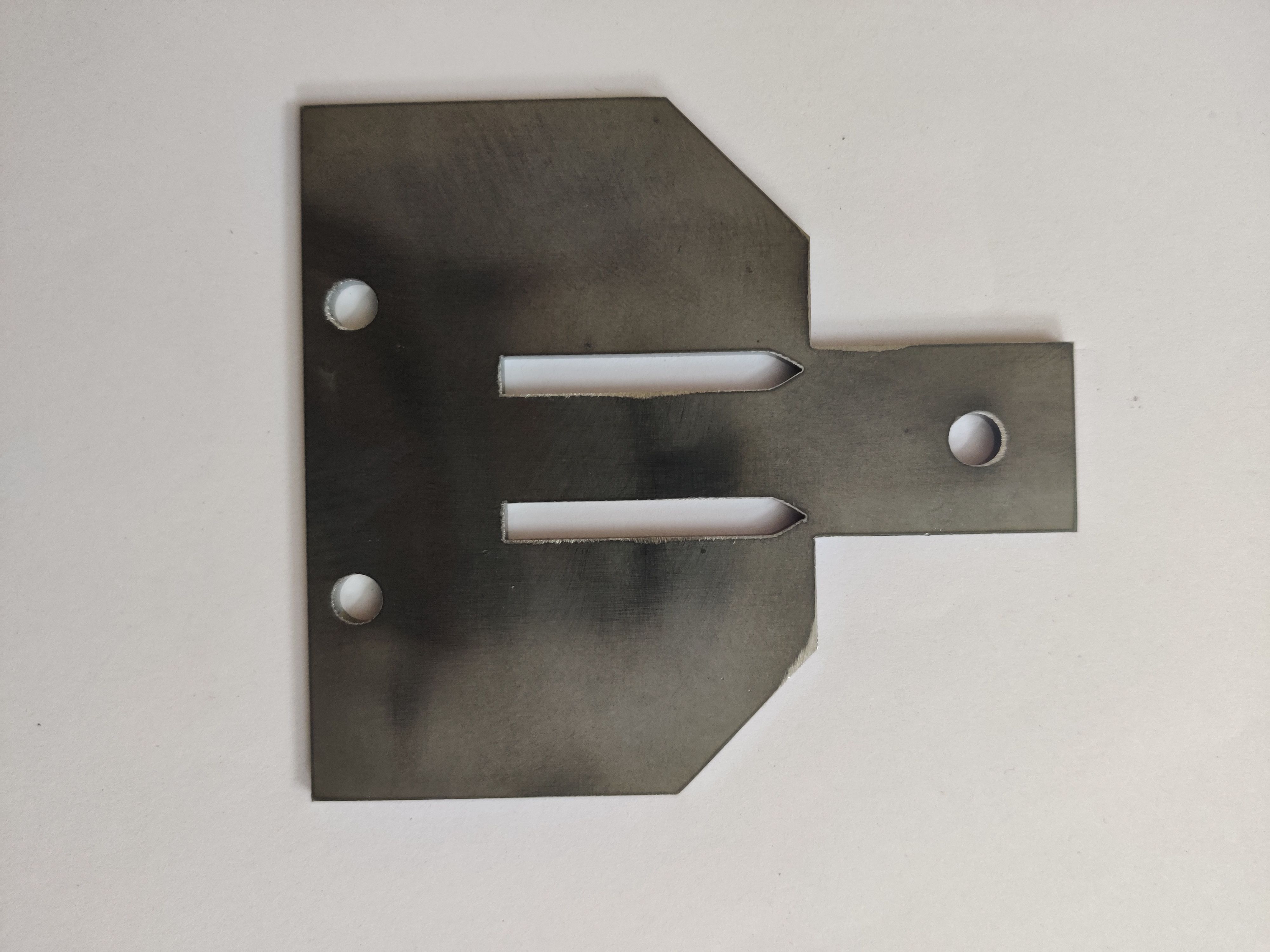

Laser Metal Cutting Service

Price 100 INR/ Kilograms

MOQ : 1 Kilograms

Laser Metal Cutting Service Specification

- Cutting Speed

- High (varies with material type and thickness)

- Edge Quality

- Smooth, burr-free finish

- Lead Time

- Quick turnaround (as per order size)

- Job Work Offered

- Custom designs, prototyping, and batch production

- Maximum Sheet Size

- up to 3000 mm x 1500 mm

- Accuracy

- 0.1 mm

- Laser Power Output

- 1 kW 6 kW (as per requirement)

- Automation Grade

- Automatic

- Suitable Metals

- Mild Steel, Stainless Steel, Aluminum, Copper, Brass, and more

- Supported File Formats

- DXF, DWG, and other CAD formats

Laser Metal Cutting Service Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Main Domestic Market

- West India

About Laser Metal Cutting Service

We have cnc laser cutting and cnc metal bending machine, and MIG welding machine for precision sheet metal fabrication works.We can cut mild steel from 0.8 mm to 12 mm, ss from 0.8 to 6 mm and AL from 1 to 3mm.

Precise Laser Cutting Capabilities

Our service harnesses advanced laser technology to achieve high-speed, accurate cuts on a wide range of metals. The system is optimized for sheet sizes up to 3000 mm x 1500 mm, catering to large and small projects with reliable 0.1 mm tolerance. Automated operations ensure consistent results across prototypes and batches, delivering exceptional edge quality every time.

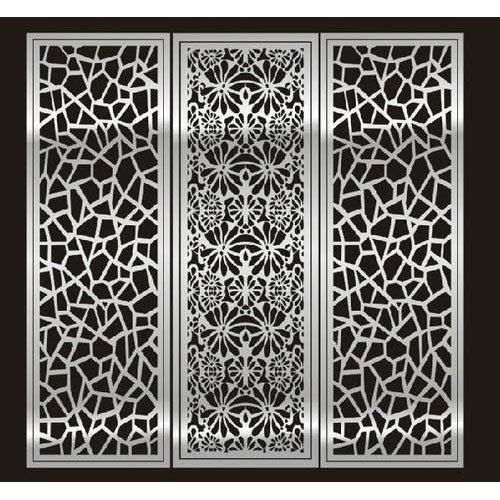

Flexible Job Solutions & CAD File Support

We accept designs in DXF, DWG, and other CAD file formats, offering flexibility for custom engineering, prototyping, and bulk production. Our automated workflow streamlines cutting, allowing you to move from concept to finished part with minimal hassle. Each job is tailored to your requirements, maximizing productivity and design complexity.

Fast Turnaround for Diverse Industries

Our quick response times give a competitive edge, whether you need single components or high-volume production runs. We serve manufacturers and traders alike, with the capacity to process mild steel, stainless steel, aluminum, copper, and brass, among other metals. Benefit from our comprehensive support and expertise, from inquiry to delivery.

FAQs of Laser Metal Cutting Service:

Q: How does your laser metal cutting process achieve such precise accuracy?

A: Our automated laser machines use advanced control systems and high-resolution optics to maintain an accuracy of 0.1 mm. This ensures every cut meets stringent dimensional requirements across diverse metals and thicknesses.Q: What types of metals can you cut with your service?

A: We support mild steel, stainless steel, aluminum, copper, brass, and several other sheet metals. Our technology accommodates various material types and thicknesses, tailored to project specifications.Q: When can I expect delivery of finished laser-cut parts?

A: Delivery times are rapid, with turnaround depending on job size and complexity. Most orders are processed quickly, and we prioritize efficiency for both prototyping and batch production demands.Q: Where is your laser metal cutting service available?

A: Our services are available throughout India, catering to manufacturers, service providers, suppliers, and traders in multiple industries.Q: What file formats do you accept for custom designs and production jobs?

A: We accept DXF, DWG, and other widely used CAD formats, allowing seamless integration of your designs into our automated cutting workflow.Q: What edge quality can I expect from your laser cutting service?

A: Our technology provides smooth, burr-free edges, reducing the need for secondary finishing and ensuring optimal part quality for immediate use or assembly.Q: How can I benefit from your automated laser cutting solutions?

A: Automation enables faster production, consistent quality, and cost-effective processing of custom and batch jobs. Youll achieve accurate results with less manual intervention and streamlined project management.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS